Oxygen generators

More informationAbout oxygen generators

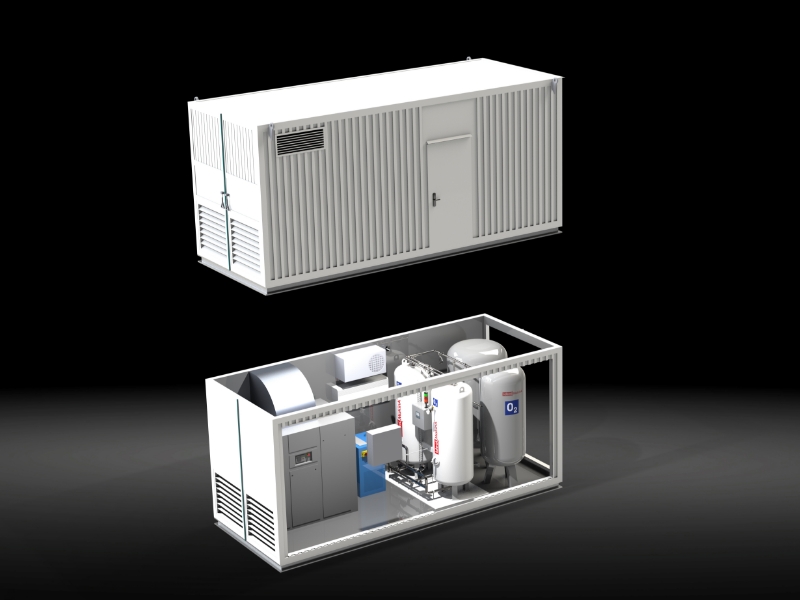

The technology of generating air to oxygen through the use of adsorption processes in PSA oxygen generators is well studied and is widely applied in industrial facilities for the recovery of high purity oxygen. This is then used in various sectors such as medicine. At an industrial level in the glass sector, blast furnaces, waste treatments, biogas plants, oxygen laser cutting, etc ...

PSA oxygen generators are designed to produce high purity oxygen by regulating gas adsorption and adsorbent regeneration by changing pressures in two adsorbent container vessels (Zeolites). This process needs a constant temperature, close to room temperature.

The process of inversion adsorption in each of these adsorbers consists of two stages operating at intervals of a few minutes. In the adsorption stage, nitrogen, moisture and carbon dioxide molecules diffuse into the porous structure of the adsorbent, while oxygen molecules are allowed to pass through the adsorber container and be distributed in the form of high-purity oxygen.

Sectors and application

- Hospitals

- Piscifactories

- Cutting welds

- Biogas Plants